News from the Trimborn Maschinenbau GmbH

January 2024 – sustainability

In January 2024 the company did in cooperation with the Handswerkskammer Aachen a sustainability check. This check is based on the “Sustainable Delevolpment Goals” from the UN. This check ascertained our status quo. After the successful evaluation from the HKW Aachen the Trimborn Maschinenbau GmbH knew that the implemented projects in the sustainable area were effective. Furthermore the company is wiling to reach their amount of future climate objectives.

December 2023 – social commitment

The Trimborn Maschinenbau GmbH supported the local project “Stark für Kinder”. This project provides help for families, which need help because of strokes of fate. Specially the help is for the childrens of those families. As example this organization builds a sports area in our local town for kids. Our company handed over a donation just shortly before christmas. We hope that a lot of childrens enjoyed the holidays because of the help of this society.

December 2022 – social commitment

The Trimborn Maschinenbau GmbH supported the local project “Stark für Kinder”. This project provides help for families, which need help because of strokes of fate. Specially the help is for the childrens of those families. This society organized a christmas evening for those childrens. Our company handed over a donation just shortly before christmas. We hope that a lot of childrens enjoyed the holidays because of the help of this society.

October 2021 – Investments for an ecofriendly production site

The Trimborn Maschinenbau GmbH installed their first electric charging station for electric cars. The usage of the charging station is only permitted for our employees. Furthermore, the whole roof of the production site is packed with a photovoltaic system. Especially in the summer months the company is able to produce the required energy, which is needed for the production machines, on their own. This are the first steps to decrease the CO² emission and to cope with the climate protection goals. More arrangements to satisfy those goals will be implemented if they’re possible.

![]()

August 2021 – Expansion of our milling machinery

Despite all the limitations due to the pandemic the Trimborn Maschinenbau GmbH invested in a new 5-axis milling machine. The DMU 75 MonoBlock from the company DMG MORI AG includes a tool chain with a capacity for 180 tools. Time consuming and expensive set-up times can be shortened in consequence of this big tool chain. An automatic pallet changing system with different pallet sizes is also linked up with the machine. This system can handle parts with a weight up to 300 KG. On grounds of that the Trimborn Maschinenbau GmbH is capable to produce automatized a big amount of different parts.

March 2021 – News

From now on we can offer you a new coating. We found a trusted partner, who can do gold coating in very good quality. In addition we invested in our CAM software “SolidCAM”. We’re able now to mill and drill parts with 5-axis simultaneously. This allows us, to produce very complex parts with varying radii and undercuts.

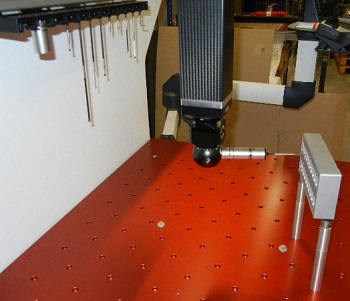

September 2020 – Implementing of the first CNC coordinate measuring machine in the company history

Our modern machinery is now equipped with a 3D-coordinate measuring machine. This machine is from the company Wenzel and the type is a SF87. The company Klostermann installed the machine in August. After a successful training in September, we started to measure our parts with this new CMM. One feature of the machine is a swivel head from Renishaw. The dimensions of the working area are 800 x 700 x 700 mm. From now on we’re able to solve complex measuring tasks with a high process reliability.

July 2020 – Successful routine surveillance visit for the DIN ISO 9001:2015

After the recertification last year, was the annually routine surveillance visit scheduled for July.

This was succeeded without any critical deviation.

May 2020 – New turn mill machine center with automation

In the middle of the coronavirus crisis our newest machine investment was delivered to our company. This turn & mill machine center was fabricated by DMG Mori. The CTX Beta 1250 TC is stocked with an automation interface and the corresponding robot.

This robot loads and unloads automatically parts to or from the machine. The maximum part diameter for the robot is from 10 mm to 180 mm. Through this extension our machinery in the turning area has a higher capacity for future orders, where a higher number of difficult parts are required. We’re now able to produce those orders even more economical and accurate. The combination of machine and robot pointing out that our machinery is on the state of the art.

February 2020 – New turning machine

We have extended our machinery with a turning machine from the company Chevalier. On the basis of this machine we’re able to raise our

capacity in the small-series production section. This is the result of the 8-tool-turret, which is installed on this machine. Furthermore, the

modernity of our machinery stays at a high level. This turning machine was delivered in February 2020 and got directly into operation.

January 2019 – New machine for the parts labeling area

Through our newest investement the machinery raised and includes now a new kind of a machine. From now on almost every part can be

marked with our new Laser marking machine ETL 720 X2. Based on the integrated rotary axis round parts can be marked at the

circumference with a high precision.

May 2018 – New ultra-modern 5-Axis milling machining center Hedelius Acura65 with standby magazine and pallet changing system

Through our newest investement the machinery raised and the level of automation also raised. We’re now able to house 245 tools in one machine.

On top of that, we’ve the oppurtunity to process 24 pallets consecutively without a manual interference from one of our employees. We secure

the necessary precision of the pallets with a zero point clamping system. According to this investment the modern company philosophy

“the utmost precision” will be pursued into the future.